DESIGN AND MANUFACTURING SERVICES

We, Infinity Design, have experienced and skilled in design with knowledge of manufacturing processes and along with out manufacturing partners/sister concerns we do provide design and manufacturing services in field of heavy metal Fabrication and sheet metal Fabrication, Aluminium profile extrusion structure and various automation solutions i.e., linear actuator, special purposes machines, pick and place systems etc.

Fabrication design and manufacturing services:

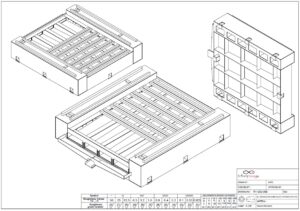

At Infinity Design, we have highly qualified drafters that utilize the latest CAD technology to its best potential to produce a comprehensive range of fabrication drawings for commercial, industrial, and residential structures.

We are able to draft column connection to foundation with base plate details, along with other connection details, such as riveted, welded or bolted connections. In addition, we can lay out connection details for moment resisting or ordinary moment resisting frames. The following are some of the other fabrication drawing services that are included:

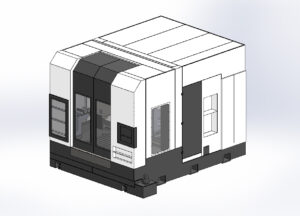

- Machine enclosure I.e. Machine tool industry, laser

cutting machine, special purpose machine etc. - Sheet metal parts

- Electrical enclosures/ cabinet

- Tool Storage cabinets and trolley

- Structure

Aluminium extrusion profile structure:

Infinity Design is a leading Aluminum section assembly modeling service provider and can help you address a very wide variety of Aluminum assembly modeling requirements. We perform highly accurate 3D modeling of various parts using advanced software tools and technologies to make your assembly design error-free. Our solutions also enable easier analysis and evaluation of your parts and assemblies. With us by your side, you can confidently take your designs to the manufacturing phase.

Machine Guarding: Keep your equipment and employees protected with specialty-engineered machine guarding. Safety precautions are often neglected until problems are apparent. Maintaining a safe workplace environment has benefits beyond productivity up-time and minimising worker injury. Product quality and employee morale will increase, while employee turnover will decrease, making guarding well worth the investment.

Types of Machine Guarding:

- Lifting door machine enclosure

- Sliding door machine enclosure

- Full or half covered machine enclosure

Machine Framing: Structural frames can be built for most projects using modular extruded aluminium framing. Structural project sizes range from inches to hundreds of feet, depending on customer requirements. Aluminium profile system engineers can customise your frame based on the load requirements. This is dependent on the profile choice.

One of the many long-term benefits of using a modular extruded aluminium framing system for your safety project is that it allows for machine guarding and industrial partitions to be disassembled and reassembled with updates as needed. This flexibility of design allows for safety guarding expanding with workflow processes and innovations over the long-term.

Types of Machine Framing:

- Framing for Linear motion

- Framing for Lean production

- Framing for safety enclosure

- Framing for enclosure

Safety Partitions Wall: Safety Partitions can be placed anywhere on the manufacturing floor to act as a barrier between common work areas and high traffic areas. At a standard height, these partitions are free-standing and act as a divider between machines and dangerous areas. Partitions typically use polycarbonate for their panelling selection, however mesh in a variety of colour options and other material choices are also available.

Types of Partition Walls:

- Polycarbonate guarding wall

- Mesh Partition Guarding Wall

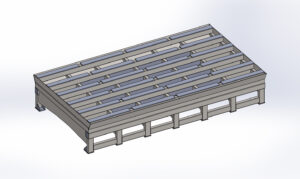

Work station: Each workstation build is engineered from a team with vast experience of designing custom industrial workstations for precise applications. From manufacturing, testing, maintenance, to assembly line work cells, with an assortment of multi-functional stations. The extensive array of accessories and components assures that your work environment has the functionality to optimize any worker process. Height adjustable tables are available to ensure workbenches are the perfect height for any worker. By utilising standard T-slot grooves, it is simple to integrate linear motion, install workflow roller conveyors, and add computer components to industrial workbenches.

Workstation expands using the inherent versatility of T-slotted aluminium profile allows for simple integration of lean production systems into workstations for labour efficiency. Linear motion, flow racks, conveyors, and other dynamic components can be included as add-ons to increase your workflow capabilities. Each workstation is custom engineered for precise industrial and lean workstation solutions.

Types of Workstation:

- Office workstation

- Inspection workstation

- Manufacturing workstation

- Lean manufacturing workstation

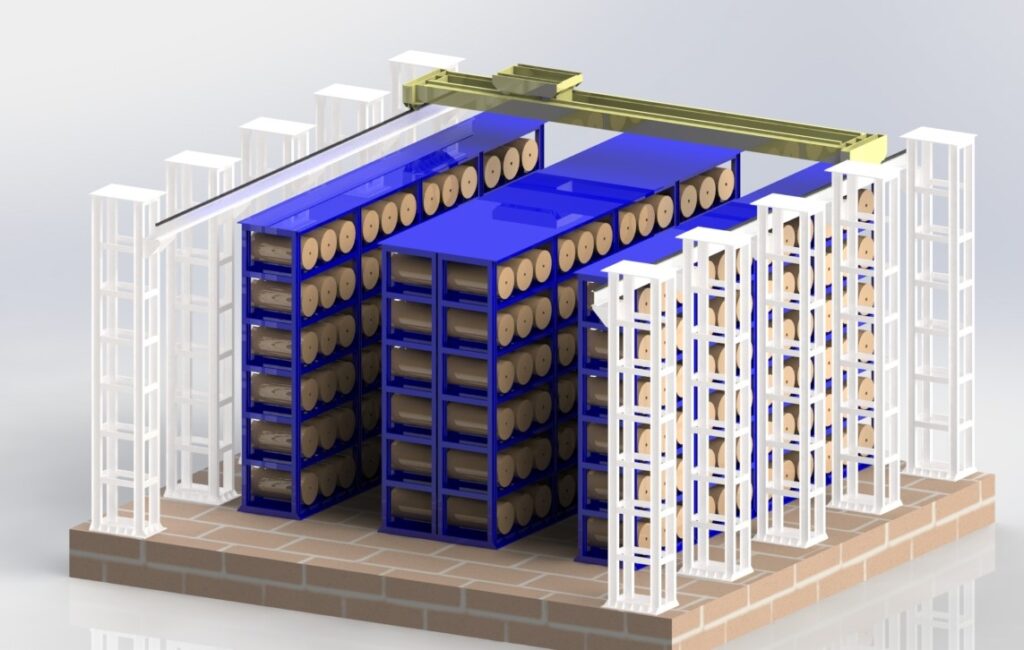

Miscellaneous Structure: Using aluminium profile systems, we are capable of designing structural assemblies for any situation. These units can be used in conjunction with all of the profile dynamic components. Turning your simple overhead gantry structure into a possibly 3-Axis pick-n-place system, Trolley for storage, Racks for material storage etc.

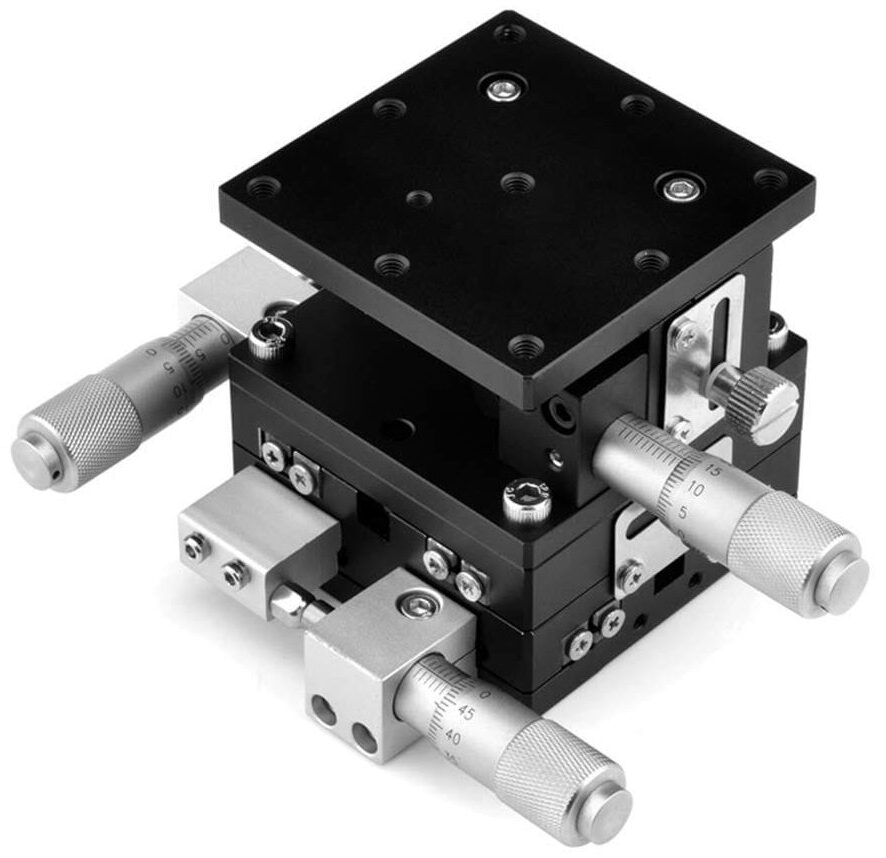

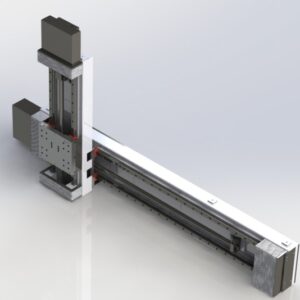

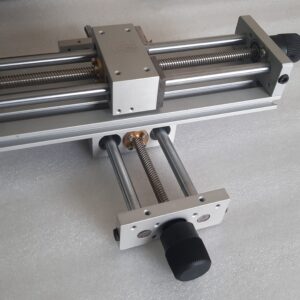

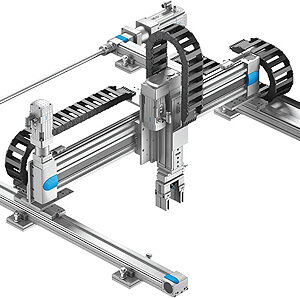

Linear axis/actuator, Pick-n-place system and special purpose machine:

At infinity design we design customised linear actuator/axis, pick n place systems by using pneumatic, electrical and mechanical integration for various travels, load carrying capacity and for various mounting position i.e. horizontal, vertical and at any angle.

We are also design and manufactured various Special purpose machines with different applications. From conceptual schematic drawing of machine to final design and detail drawing of each part for manufacturing.